Real-World Success Stories Powered by Niraltek

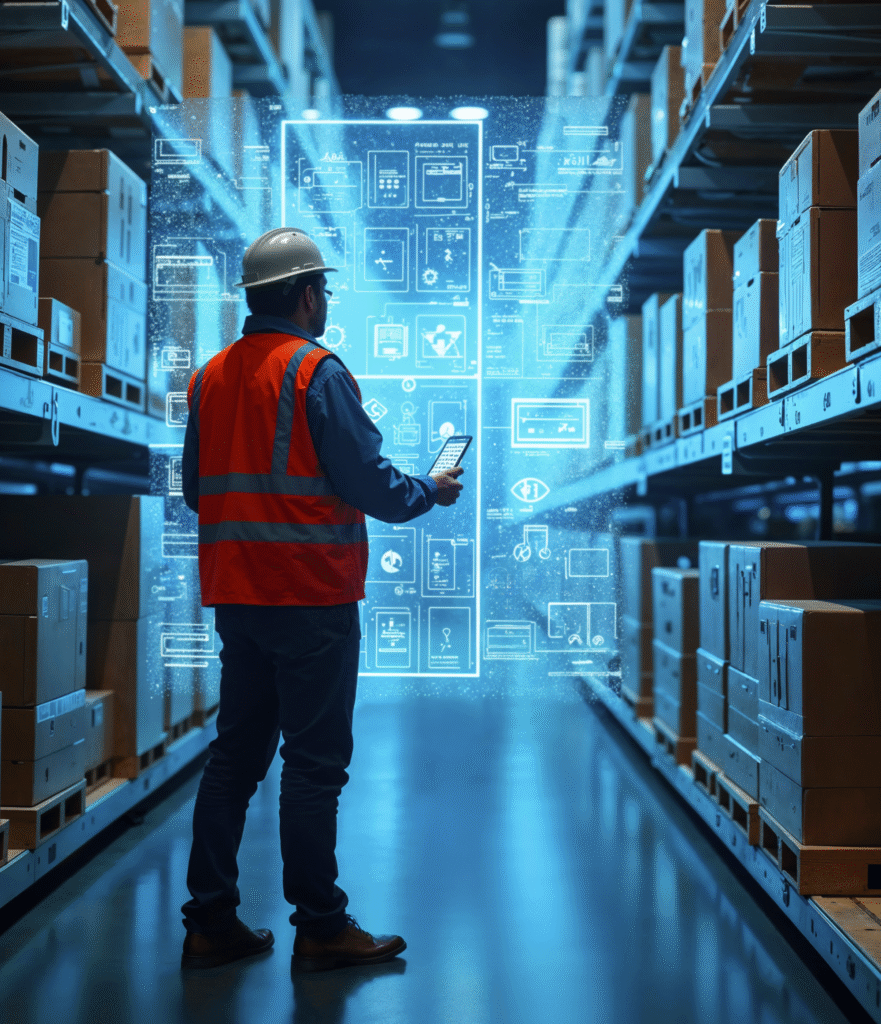

At Niraltek Solutions, we don’t just build products—we deliver results. Our case studies showcase how our IIoT-based monitoring and automation systems are transforming industrial operations across sectors like steel manufacturing and cold storage logistics.

Steel Manufacturing Monitoring

Challenge:

The plant faced high energy consumption, lack of visibility into machine uptime, and unexpected breakdowns during production cycles, affecting output and maintenance costs.

Our Solution:

Niraltek implemented a comprehensive IIoT-based monitoring system to track energy usage, motor health, and real-time machine performance. The system included edge-based controllers, sensor networks, and a cloud dashboard with predictive maintenance capabilities.

Impact:

- Reduced downtime by 22%

- Achieved 15% energy savings within the first quarter

- Real-time alerts enabled faster response to anomalies

- Enhanced production planning through data insights

Cold Storage Monitoring

Challenge:

Temperature fluctuations in cold rooms and trucks led to spoilage risks and compliance issues. The client needed a scalable system to monitor multiple cold storage units across locations.

Our Solution:

We deployed wireless sensor nodes and cloud-connected gateways to monitor temperature, humidity, and energy parameters in real time. Our platform provided instant alerts, remote access, and automated reports to meet regulatory standards.

Impact:

- Achieved 100% temperature compliance

- Reduced product spoilage and energy wastage

- Enabled remote monitoring of cold rooms and fleets

- Improved operational efficiency and audit readiness